External profiles are the basic structural elements in use in the construction industry to mount facade claddings. Their diversity makes it often difficult to decide what type of components to choose. Find out which profiles will ensure permanent and safe mounting of ventilated facades!

Types of construction profiles

When choosing profiles for a given project, quite a few important parameters are taken into account. It is worth dividing the profiles into three categories: type of material they are made from, cross-section and how the profiles are produced. These data tell us the most important features of the product.

- Classification according to the type of material they are made from:

- stainless steel profiles,

- steel profiles with metallic Magnelis® coating,

- aluminium profiles.

AGS Company offers both aluminium profiles and Magnelis® coated black steel profiles – they make up currently the most competitive solution, both in terms of price and quality.

Although apparently these profiles look almost the same, they differ to a great extent. Aluminium belongs to relatively light materials with a high conductivity of heat and electricity. However, it is worth noting that black steel has a higher density, which is extremely important as it translates into the strength of the material. In the construction industry, the profiles’ resistance to high temperatures is also of great importance. When designing ventilated facades, attention shall be paid to the legal regulations being in force. Paragraph § 225 of the Technical Conditions, which depicts the conditions that shall be met by buildings and their location is of particular importance:

Elements of facade cladding shall be mounted to the building structure in a way to prevent their falling off in the case of a fire in the time below that required by fire resistance class for the external wall, set out in § 216 subpara. 1, according to the fire resistance class of the building where they are mounted.

Stainless steel profiles or steel profiles with Magnelis® coating are the answer for project owners interested in energy-saving and innovative solutions. Profiles with an anti-corrosion coating will prove to be efficient in particularly difficult, aggressive environmental conditions (up to corrosivity class C5), which is due to the use of stainless steel or black steel with an innovative coating, an alloy of zinc, aluminium and magnesium.

Passive solutions are characterized by increased corrosion resistance compared to aluminium profiles.

AGS profiles have been tested for ventilated facades fire resistance in case of fire. The conducted tests confirm that the requirements of §225 of the TC are met.

- Cross-section type-related division:

- closed profiles,

- open profiles.

The target use and durability of the profiles depend on their shape. The choice of closed or open elements shall be based on the analysis of loads that will be acting on the sections. If the values are relatively high, it is worth choosing closed profiles.

- Production method-related division:

- cold-rolled profiles,

- hot-rolled profiles,

As their names suggest, the technology used in their production differs cold-rolled from hot-rolled profiles. High force is used to bend profiles, which contributes to an increased strength and plasticity of the finished element. As to hot-rolled sections they are resistant to high loads and maintain the same hardness on the whole surface of the element.

What profiles will you find in the AGS offer?

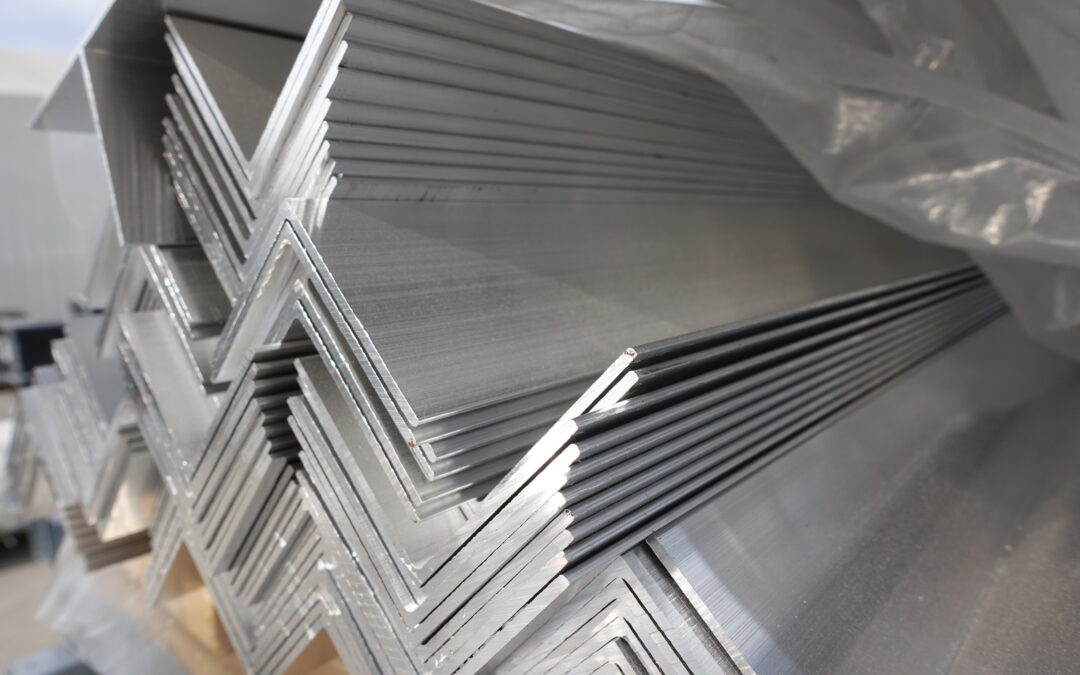

- aluminium angles and Magnelis® used as vertical profiles in the indirect support of the facade cladding panels,

- aluminium tee bars and Magnelis®, which means vertical profiles used to connect/support two adjacent facade cladding panels,

- C-profiles, Z-profiles and omega Magnelis® profiles – for vertical or horizontal use,

- W1 Magnelis® profiles, which means point/piece profiles, mounted to continuous vertical profiles (with their application you can hang facade cladding in an invisible way – the so-called hanging manner),

- Magnelis® corner profiles designated to mount two panels neighbouring in the corner,

- A, F, U, Z aluminium profiles.

The undeniable advantages of the Magnelis® coating are:

- compatibility with alkaline building materials such as concrete or mortar,

- reduced environmental impact due to a 75% lower zinc content and up to 75% slower zinc rinsing,

- secondary coating processing in a 100%,

- compliance with the LEED and BREEAM certification requirements.

How can AGS structural profiles be used in passive construction?

The ventilated facades mounting systems designed and manufactured by AGS make up a component that ensures excellent thermal insulation of buildings. The choice of a given solution depends on several variables – these include among other things:

- type of material the walls are made of,

- type and thickness of thermal insulation,

- type of cladding,

- mounting of cladding,

- wind and corrosion zone.

When you make up your mind to cooperate with AGS, you can be sure that you will easily match the appropriate facade mounting system to your project. We have our own machine park, we make individual mounting designs with the support of our engineers. Thus, most products of our offer can be matched with each project – both in terms of planned openings for profiles, change in their length and cuts.