FACADE SYSTEMS

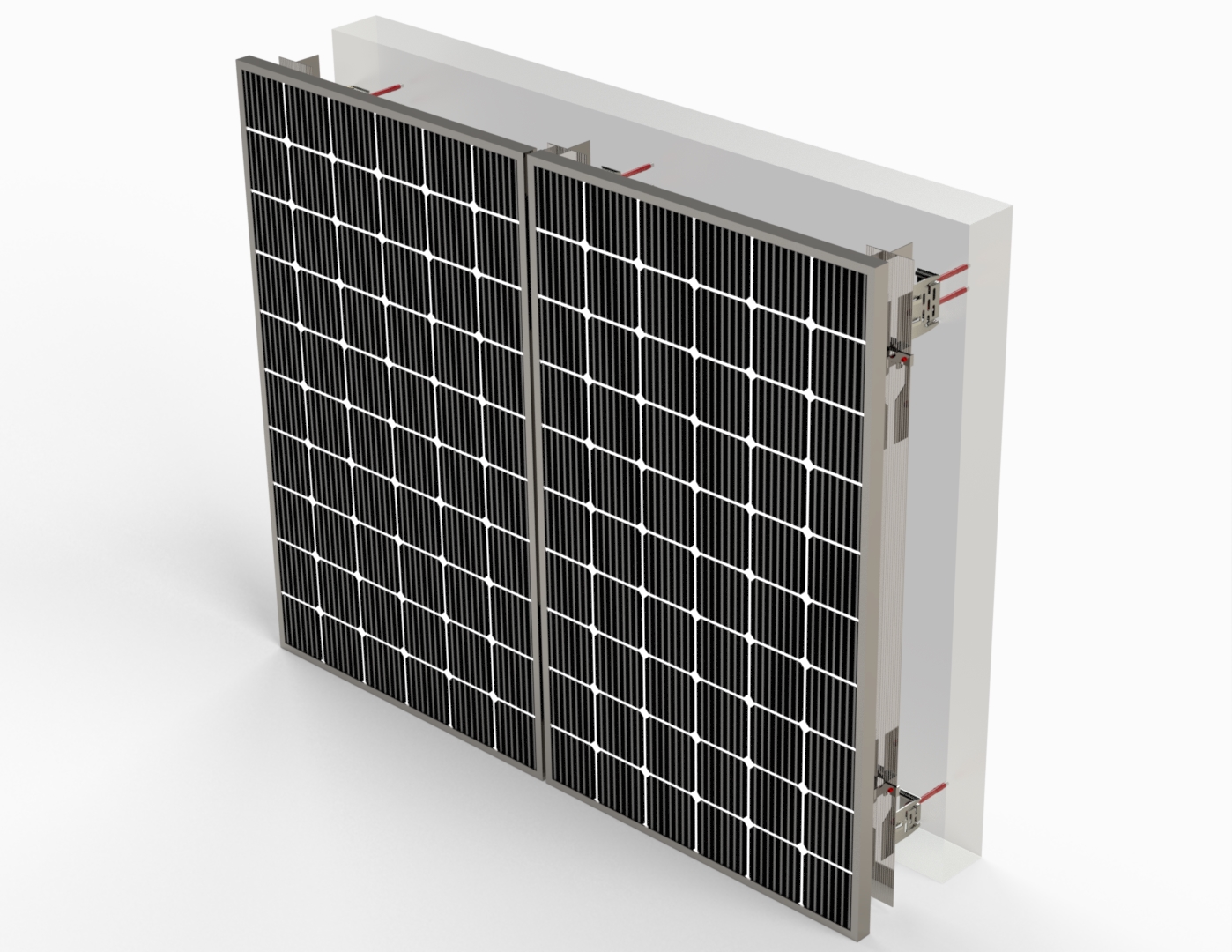

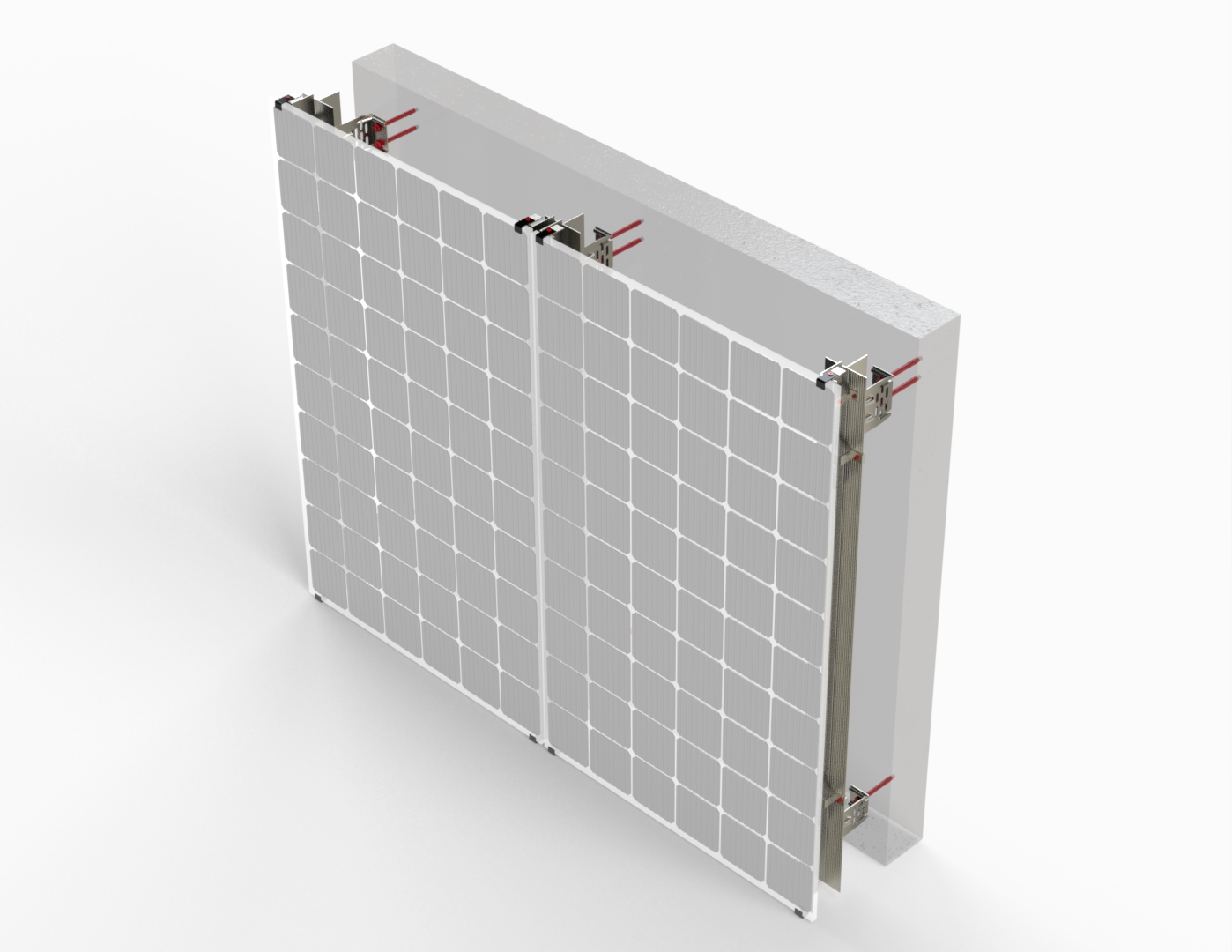

BIPV systems from AGS are two types of systems for mounting photovoltaic modules on the facade wall: glued and mechanically fixed. Glued substructures are used to assemble frameless modules – glass-glass type, while mechanically fixed substructures are used to assemble modules with frames. In both solutions, it is possible to mount both vertically and horizontally.

BIPV system from AGS – an innovative way of mounting photovoltaic panels on the facade

Based on applicable legal regulations, it is assumed that photovoltaic structures should be mechanically attached to high-rise buildings (i.e. over 25 m above ground level). In this case, the substructures should also be made of non-flammable materials. It is worth emphasizing that BIPV systems produced by AGS are materials with confirmed fire-fighting properties, therefore they are classified as fire-retardant. In the event of a possible fire, the mountings should maintain their integrity, which means that appropriate conditions will be provided for the evacuation of people within no longer than 120 minutes.

Photovoltaic structure on the facade, the so-called The BIPV system by AGS has a 20 mm gap between the insulating material and the surface cladding. The structure was designed to improve the thermal insulation of the facility and ensure proper moisture removal. The system is based on steel passive consoles, covered with an innovative metallic coating, ensuring long-lasting anti-corrosion protection.

Insulation parameters of AGS facade systems

Installing PV panels on a building’s facade requires compliance with applicable regulations and legal conditions. When implementing such an investment, it is necessary to take into account the building’s thermal protection, operational safety and fire safety. AGS offers exceptionally safe and durable solutions in this area.

The most important features of AGS BIPV systems include:

- meeting the new requirements of the Technical Conditions related to the heat coefficient (Ucmax= 0.20 W/m2⋅K);

- meeting the requirements of §225 of the Technical Conditions regarding facade cladding not falling off within 120 minutes;

- corrosion resistance up to environmental corrosion class C5.

These parameters make AGS facade systems significantly superior to products from other companies. Their properly designed structure and made of stainless steel or GD 350 steel covered with Magnelis® anti-corrosion coating guarantee compliance with stringent legal requirements regarding the solutions offered. This is a special coating that guarantees protection in even the most aggressive environmental conditions up to corrosion class C5 and ensures fire resistance up to 120 minutes. Fire resistance confirmed by tests and the National Technical Assessment prove the highest quality of AGS.

Types of BIPV systems from AGS

Our offer includes several types of photovoltaic structures for a vertical wall, the so-called BIPV system:

- Glued BIPV is a system using point profiles enabling the installation of a facade system intended for frame modules in a vertical orientation. Fastening is done mechanically,

- Mechanically fixed BIPV is a system using point (short) profiles that allow the installation of a facade system intended for frame modules in a horizontal orientation. Here, the mechanical method is also used for assembly,

We have our own Design Department, which, in addition to designing individual PV structures for facades, provides professional advice and guarantees the highest quality. More detailed information about our BIPV systems can be found below.

We also produce other fastening systems, e.g. mounting profiles used as grids for mounting external cladding, such as aluminum profiles or steel profiles. We encourage you to check out our offer!