The material from which various types of objects are made has always determined their quality and durability. However, it is primarily the construction industry that bases its reputation on the raw materials used in production. This is mainly related to the high responsibility of designers for the safety of use of entire structures, which should meet the applicable occupational health and safety and fire protection requirements without any failures.

AGS focuses its activities on creating construction fastenings with the best technical features on the Polish and foreign markets. For this purpose, it was necessary to select the most weather-resistant steel, enabling the products to maintain excellent quality for many years. What is Magnelis® steel and why are products with this coating the best alternative to the well-known aluminum or stainless steel?

What is Magnelis® steel?

Magnelis® steel is black steel with an innovative metallic coating. It consists of an alloy of three elements: zinc (93.5%), aluminum (3.5%) and magnesium (3%). Tests carried out in a salt chamber confirmed the high resistance of the raw material to corrosion under conditions of continuous exposure of the sample to the aggressive effects of sprayed brine. Tests in the so-called salt fog are an excellent – and above all fast and accurate – way to check whether and at what rate the material corrodes.

The use of Magnelis® steel for the production of ventilated facade mounting systems and building connectors is dictated by, among other things:

– compatibility with alkaline building materials such as concrete or mortar,

– reduced environmental impact thanks to 75% lower zinc content and up to 75% slower zinc leaching process,

– possibility of 100% secondary processing of the coating,

– meeting the requirements of LEED and BREEAM certification.

In addition to the anti-corrosion properties of Magnelis® steel, its self-healing properties play a key role. This is particularly important in the production of construction connectors – profiles, as well as passive consoles with numerous perforations. When using steel with a layer of Magnelis® metallic coating, the places of cutting and drilling elements are also protected against corrosion. The passive layer migrates from the coating to the cutting edge, thanks to which the formation of red rust is blocked. Interestingly, the self-healing effect works even with scratches caused during transport or installation.

Invest in corrosion-resistant AGS solutions

If you want to implement a durable and safe construction investment, consider using the AGS offer, which includes, among others:

– Magnelis® steel passive consoles,

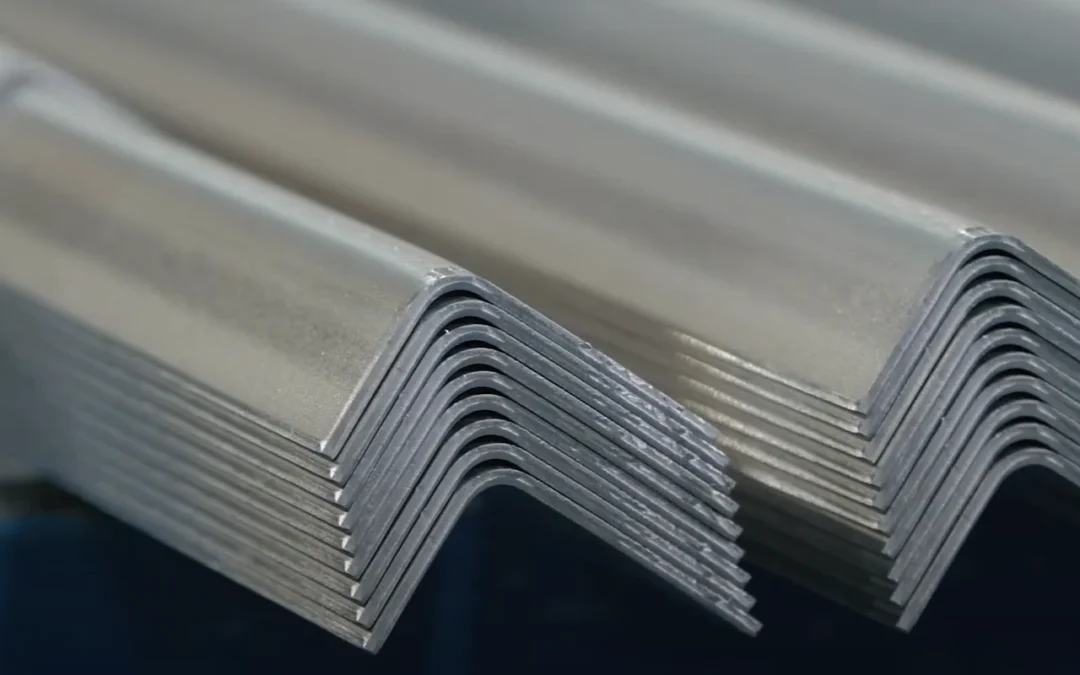

– Magnelis® steel angle profiles,

– Magnelis® steel T-bars,

– Magnelis® steel channel sections,

– Magnelis® steel Z-sections,

– Magnelis® steel omega profiles,

– W1 steel Magnelis® profiles,

– Magnelis® steel A profiles,

– Magnelis® steel corner profiles.

The wide product offer is also complemented by recently popular photovoltaic facades, which enable the installation of PV modules on building walls. Contact AGS advisors to learn about the detailed scope of the company’s services!